Ecotron will build a million-ton 100% bio-based PBS project

Latest News: Recently, the synthetic biology company “Tichuang Bio” launched the biodegradable material PBS (polybutylene succinate) project, and cooperated with the team of Jiang Min, a professor and doctoral supervisor of Nanjing University of Technology. Cooperation, plans to land in Guangzhou. Tichuang Bio has introduced the technology of biosynthesis of succinic acid, including the construction of succinic acid production strains, the strain culture and fermentation process, and the purification process of succinic acid.

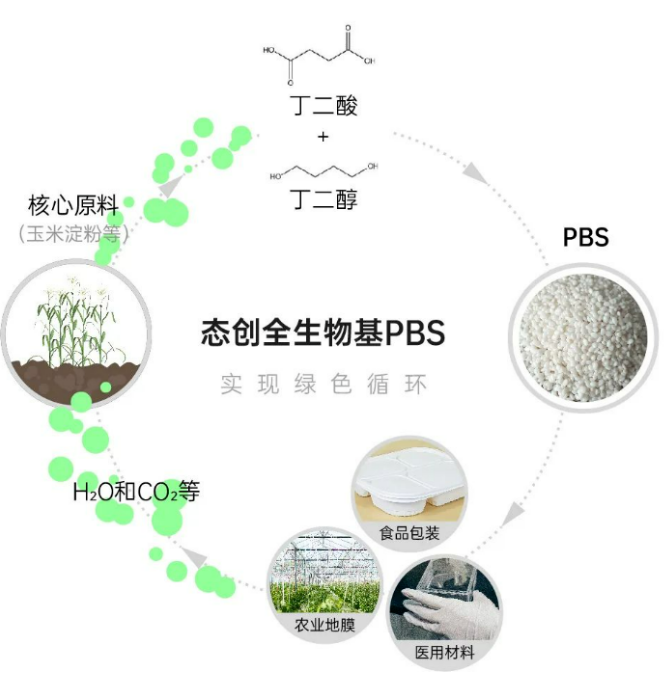

Bio-based PBS is a biodegradable plastic that can be used in disposable tableware, cosmetic bottles, medicine bottles and other scenarios. Because bio-based PBS can be degraded into H2O, CO2 and other substances under the action of bacteria or enzymes, it is harmless to the environment. In the era of carbon neutrality, it is favored by international giants and is expected to replace general polyethylene and polypropylene. Enter the field of general plastics. In the past, bio-based PBS failed to enter the market well within a certain stage due to its high cost.

Bio-based PBS is prepared by polycondensation reaction with bio-based succinic acid\bio-based butanediol as raw materials, adding high-efficiency catalysts. Nanjing University of Technology has a long-term technical accumulation in the biosynthesis of succinic acid, the core raw material of bio-based PBS; Professor Jiang Min is under the tutelage of Ouyang Pingkai, an academician of the Chinese Academy of Sciences, and the succinic acid industrial strain constructed by the team eliminates the need for aerobic bacteria The culture process of the body can achieve “one-step anaerobic”, and the concentration of succinic acid is >70

g/L; using carbon capture technology, 1 kg of succinic acid can be produced to fix 0.37 kg of carbon dioxide.

1,4-Butanediol (Bio-BDO), another raw material for the production of PBS by synthetic biology, is researched and developed by State Chuang Bio, and is expected to be trial-produced in the third quarter of 2022. At present, domestic BDO production is mainly petroleum-based, and bio-based BDO currently has a global production capacity of more than 65,000 tons/year, mainly concentrated in Germany, the United States, Japan and China.

It is understood that the company has carried out a number of industry-university-research cooperation with Sun Yat-sen University and Jiangnan University, and the cooperation with Nanjing University of Technology is based on helping the realization of the “dual carbon” goal and reducing environmental pollution. , mass production is expected by the end of the year. In terms of technical cooperation, Tichuang Bio will apply the scientific research results of PBS of Nanjing University of Technology to industrial production through the platform mass production technology, and further optimize the process.

Tichuang Bio was established in February 2021. In March this year, it announced the completion of the A+ round of financing of over US$100 million. Before that, substances in consumer application scenarios such as small molecule peptides and erythritol have been mass-produced. In response to the commercialization goal of large-scale PBS projects, Transchuang Bio plans to optimize the cost of mass production of PBS within 2022, and simultaneously start to provide samples for performance testing, and enter the market by the end of the year.