The screw zinc coating turns white and black after neutral salt spray. Let’s learn how to solve it together?

|

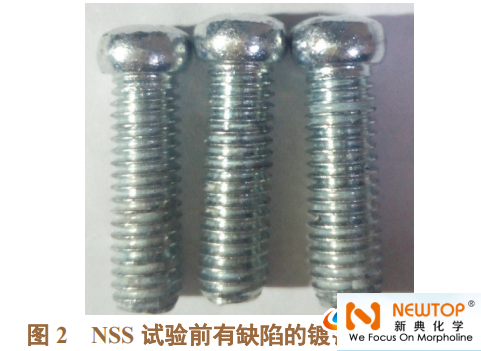

galvanized fasteners (such as screws, nuts, etc.) have a wide range of applications in various industries such as auto parts, electrical appliances, electricians, and hardware tools. The sockets, wall switches, and digital products of the author’s company basically all have corresponding galvanized fasteners. The galvanized screws (2~5g/piece) of a certain foreign trade spool product require the thickness of the zinc layer to be above 5μm, and also have certain requirements for environmental protection, product appearance, and corrosion resistance. After 48 hours of neutral salt spray (NSS) test of this product, there were peeling and black spots on the surface of the nut, and the thread was whitish (see Figure 1), which seriously affected the progress of the entire spool product project. 1 Process flow and operating conditions of acid barrel galvanizing Loading → pre-degreasing → degreasing → hot water washing (60~80°C) → 2 washings → pickling → 2 washings → barrel galvanizing → 2 washings → light emitting → washing → blue and white passivation → 2 washings → sealing → 2 washings → drying. 1. Pre-degreasing QSD901 degreasing powder (Ningbo Linghang) 30~50g/L, temperature 60~80°C, time 10~30min. 2. Degreasing QSD901 degreasing powder 30~50g/L, temperature 60~80°C, time 5~10min. 3. Pickling with 10%~15% (volume fraction) hydrochloric acid for 3~5min. 4. Barrel galvanizing of potassium chloride 180~250g/L, zinc chloride 50~100g/L, boric acid 25~35g/L, loading capacity 50.0~62.5g/L, drum diameter 400mm, drum length 600mm, drum speed 4 ~6r/min, liquid level height 1300mm, voltage 11~13V, time 5~6h. 5. Light emission of 0.5% (volume fraction) nitric acid, time 10~15s. 6. Blue and white passivation SURTEC668 trivalent chromium blue and white passivation agent (Hangzhou SurTec Chemical) 150mL/L, time 10~15s. 7. Sealing SURTEC555S sealant (Hangzhou SurTec Chemical) 20% (volume fraction), temperature 15~25°C, time 60s. The sample is required to be blue-white, able to pass the 48h neutral salt spray test (without white rust), and meet the environmental protection requirements of chromium for export products. 1 2 Features of the problem piece After observing the screws that have not been tested by NSS, it is found that the coating on the nut of all the problem parts is rough and not fine, and the coating on the thread has been whitish (see Figure 2). The thickness of the galvanized layer at the nut of the problem piece measured by an X-ray thickness gauge is 14-16μm, all of which are too thick. On the basis of the original process, the galvanized parts are immersed in anti-rust oil for 5 seconds, and the threads are still white. After 24 hours of the NSS test, black spots appear on the galvanized layer of the nut (see Figure 3). 3 Reason Analysis (1) For threaded fasteners, the general coating thickness is 5~8μm. When it exceeds 10μm, the coating surface is rough, and the adhesion to the substrate is not good, which may easily cause the coating to peel or even fall off. The black spots after the NSS test may be caused by the iron matrix being exposed and corroded after the galvanized layer is peeled off. (2) The whitening phenomenon at the thread should be caused by too long sealing time or too high concentration of sealing agent used after galvanizing. 4 Solution and its verification Scheme 1: Reduce the plating time from the original 5~6h to 2~3h, and reduce the plating thickness to 5~6μm. Solution 2: Shorten the sealing treatment time to 10~15s and reduce the volume fraction of the sealing agent to 10%. As shown in Figure 4, the galvanized screw sample obtained after the above measures was tested by NSS for 48 hours, the galvanized layer at the nut and thread was normal, and the problem was solved. |