Monobutyltin triisooctanoate

Overview:

Chinese name: 4102 Catalyst

Alias: 4102 catalyst, monobutyl tin triisooctoate, CAS 23850-94-4, monobutyl tin triisooctoate, tris(2-ethyl -1-hexanoic acid) butyl tin, butyl tin tris (isooctanoic acid), monobutyl tin triisooctoate

English name: 4102, n-Butyltris(2-ethylhexanoate)tin, -Butyltris(2-ethylhexanoate)tin, Butyltin tris(2-ethylhexanoate), Butyltrisethylhexanoatetin, MONOBUTYLTIN TRIS(2-ETHYL HEXANOATE), BUTYLTIN TRIS-2-ETHYLEXANOA, Butyltin tris-2-ethylhexoate, [butyl-bis(2-ethylhexanoyloxy)stannyl] 2-ethylhexanoate, Butyltin Tris(2-ethylexanoate), Butyltin tris(2 -ethylhexoate), Butyltris((2-ethyl-1-oxohexyl)oxy)stannane, EINECS 245-912-1,

4102, 9201, Stannane,butyltris((2-ethyl-1-oxohexyl)oxy), Butyltintris(2-ethylhexanoate) (6CI), Stannane, utyltris[ (2-ethyl-1-oxohexyl)oxy]-(9CI), Stannane, butyltris[(2-ethylhexanoyl)oxy]- (8CI), Tegokat 220, 9201, Monobutyltin tris(2-ethylhexanoate)

CAS 23850-94-4 monobutyltin triisooctanoate monobutyltin triisooctanoate n-Butyltris(2-ethylhexanoate) tin

Physical and chemical performance:

CAS 23850-94-4

EC 245-912-1

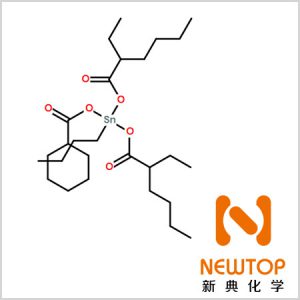

Molecular formula C28H54O6SN

Monobutyl tin triisooctoate is a light yellow transparent liquid, soluble in most organic solvents, but insoluble in water. It is a kind of esterification catalyst with low addition amount and high catalytic activity that is resistant to hydrolysis. It is mainly used for esterification and polycondensation reactions at a reaction temperature of 210~240″C, and the maximum reaction temperature can reach 250C. The catalyst is neutral, The equipment has no corrosive effect. After the reaction is completed, it does not need to be separated and does not affect the quality of the final product.

[Melting Point] -33°C

[Density] 1.105 g/mL at 25 °C(lit.)

[Refractive Index ]n20/D 1.465(lit.)

[Flash point]>230 °F

Purpose:

Yellow liquid is used to synthesize saturated polyester resin, used for powder coating and coil coating.

Other uses include:

- Aromatic polyester polyol for flexible and rigid PU foam applications

production

- Ring-opening polymerization for polymer production•Used to prepare plasticizers, including dioctyl phthalate

- For transesterification reaction, at 80℃ to 150℃

Storage and transportation:

Should be sealed and stored in a dry, cool and ventilated warehouse.

Packaging:

200KG/bucket Storage: It is recommended to store in a dry and cool area with proper ventilation. After the original packaging, please fasten the packaging cover as soon as possible to prevent the product performance from being mixed with other substances such as waterproof grade. Store in a cool, dry place, keep the container tightly closed, and avoid contact with oxides. Do not inhale dust and avoid contact with skin and mucous membranes. Smoking, eating and drinking are prohibited in the workplace. After work, take a shower and change clothes. Store contaminated clothes separately and use them after washing. Maintain good hygiene habits.