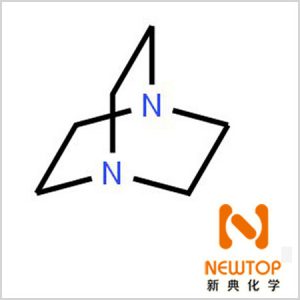

Triethylenediamine

Overview:

Triethylenediamine, also known as triethylenediamine. White or light yellow crystals. It smells of ammonia. This product is an organic synthesis intermediate, synthetic light-stable material, widely used in polyurethane foam, elastomer and plastic products and molding processes. It is also a polymer initiator, and can be used as a catalyst for ethylene polymerization and ethylene oxide polymerization, and its derivatives can be used as corrosion inhibitors, emulsifiers, etc.

| Chinese name | Triethylenediamine |

| English name | TRIETHYLENEDIAMINE |

| Don’t call | 1,4-diazabicyclo[2.2.2]octane, triethylenediamine, triethylenediamine |

| CAS login number | 280-57-9 |

| Water-soluble | Easy to dissolve |

| Outside View | white crystal |

| Triethylenediamine | TEDA | CAS 280-57-9 | Triethylenediamine | Triethylenediamine |

Basic information:

Abbreviation: TEDA

English name: TRIETHYLENEDIAMINE

Chemical formula: C6H12N2

Triethylenediamine TEDA CAS 280-57-9 Sanya Ethyl diamine triethylene diamine

Physical and chemical performance

TEDA is normally colorless or white crystals. It is easy to absorb moisture and agglomerate when exposed to the air. It is alkaline and can absorb CO2 in the air and turn yellow. Easily soluble in acetone, benzene and ethanol. Pure TEDA is very toxic. Inhalation of saturated TEDA vapor can cause slight mucosal irritation, damage to the eyes, and skin irritation can cause allergies.

Relative density (25℃): about 1.14

Melting point of pure product: 158-159℃

Flash point: 60℃

Boiling point: 174℃, easy to sublime, slightly ammonia smell

Vapor pressure: about 67Pa at 21℃, 533Pa at 50℃, 7.7kPa at 100℃

Method of making:

There are several methods for synthesizing TEDA at home and abroad. The general process is to pass an aqueous solution of amine or alcohol amine raw materials through a reactor filled with catalytic zeolite at a certain flow rate, and under the conditions of 320-400℃ and 0.3MPa The reaction, after purification, obtains TEMA.

Using piperazine and its derivatives to prepare TEDA, the product has high efficiency and the process is relatively mature to realize industrialization. However, in China, piperazine and its derivatives are small in output and high in price. However, the production of TEDA using ethanolamine as a raw material has sufficient supply, simple operation and low cost, and it is industrialized in Japan, which is feasible in China.

Features and uses

Triethylenediamine is a tertiary amine compound with a double heterocyclic structure. It is mainly used as a gel catalyst for polyurethane foam, and is widely used in soft, semi-rigid, and rigid polyurethane foams and elastomers. In addition, it can also be used for epoxy resin curing catalyst, ethylene polymerization catalyst, propylene catalyst, acrylonitrile polymerization catalyst and ethylene oxide polymerization catalyst.

Storage and transportation:

Should be sealed and stored in a dry, cool and ventilated warehouse.

Packaging:

200KG/bucket Storage: It is recommended to store in a dry and cool area with proper ventilation. After the original packaging, please fasten the packaging cover as soon as possible to prevent the product performance from being mixed with other substances such as waterproof grade. Do not inhale dust and avoid contact with skin and mucous membranes. Smoking, eating and drinking are prohibited in the workplace. After work, take a shower and change clothes. Store contaminated clothes separately and use them after washing. Maintain good hygiene habits.